Tracking Combustible Devices in a Manufacturing Environment.

Documenting Movement and Usage for Improved Efficiency and Inventory Management.

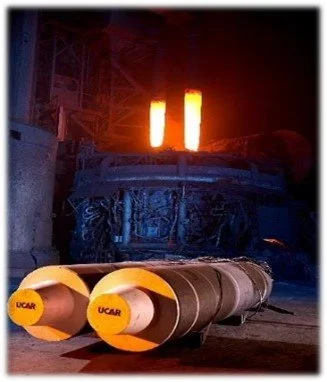

The Challenge

A manufacturer of steel products was having difficulty obtaining quality real-time data about its products’ location and usage inside plants. Lack of visibility led to a lack of understanding of how products were used, accumulated usage time, procedures around product use, and poor response to quality control issues.

The RFID READY MODBUS Data Solution

RFID READY developed a system using RFID tags and antennas installed inside the steel facilities to determine product location and provide time/date stamps for product movement. Collected information was transmitted through a serial communications protocol that delivered data in real time to the company’s backend management system. Unique alphanumeric RFID tag IDs were translated into special ID registers, and then sent to analytic and quality control applications. The data was also viewable in real time over a Web console.

Objective

To collect incendiary device data at customer facilities and report data directly into the manufacturer’s SAP system. The system was needed to improve product usage visibility, reduce waste, improve labor utilization, and provide quality control certification and documentation for customers.

Results

The solution provided low-cost visibility into single event tracking for combustible products, and satisfied the following customer objectives:

- establish time calculations for product usage

- set alerts for devices approaching time limits

- auto-generate data collection directly into existing operational systems

- provide real-time quality assurance records and work in progress reports for customers

- create better inventory management and eliminate last-minute ordering issues

- establish device performance and measurement to improve quality control

Summary

Because the solution only requires a few critical read zones within the steel plants, the RFID READY system is low cost and low risk. The solution provides the visibility required to measure usage based on time and location. It quickly assesses quality issues in near real time. The unique RFID tag numbering configuration allows the company to trace substandard or defective products back to specific manufacturing origins across multiple manufacturing plants on several continents. Reorder times are improved due to increased visibility and inventory management.