RFID product tracking from production to storage. Tracking and documenting container totes.

The Challenge

The pharmaceutical manufacturer moves product in container totes within its facilities. At any time, thousands of totes are being used for work in progress. They required real-time visibility into tote location, movement, and accumulated time at designated locations. The system focuses on three main objectives 1) better visibility, management, and reporting of tote locations 2) provide real-time dashboard visibility, alerts, notifications, and electronic (PDF/CSV) reporting as needed, and 3) reduction of manual documentation by creating digital standards within current workflow and processing.

Objective:

To implement a real-time location management system and digitization process that becomes a company standard for improved production and work in progress efficiencies. The system eliminates inadvertent product waste, improves labor utilization, and digitizes product process run certification for customers.

The RFID READY Solution

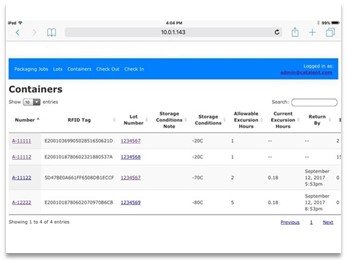

After learning the different variances in job processing, a simple user story was created that followed the tote workflow and patterns to identify the best data capture points during routine processing activities. The scans and data captures include:

Job Number/Lot Number

Storage Conditions (as defined)

Allowable Time at Location

Alerts/Notifications

Container ID (All Container IDs)

Dashboard - User Login

Staging – Begin/Commissioning IDs

Required reports in PDF or flat files.

Fixed Alerts/Alarms for emails/text

List of Standard Alerts/Alarm limits

Return prompts, close-out, email PDF.

Searchable Job logs.

Results:

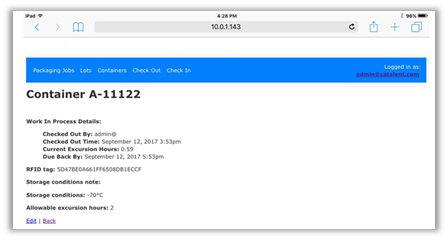

The program provided visibility into single event and cumulative location tracking for products carried in totes, and satisfied the following objectives:

-Eliminated errors in tracking and time calculations.

-Set alerts for approaching job time limits.

-Auto-generated Batch Records and log forms for manual signatures.

-Provided real-time dashboard visibility and electronic (PDF) records of product work in progress, completion and storage locations.

-Reduced manually generated documentation by creating digital standards within existing processing.

-Validated the ROI in labor savings from improved record accuracy and elimination of product waste/spoilage caused by loss products and inadvertent product excursions.

Summary

The RFID READY system eliminated manual tracking and saved many hours of labor-intensive documentation. It provided the processors with a real-time Web display of all product information including location tracking with time/date stamps. It included a RESTful web service interface, designed with hooks to integrate into the processors back-end JD Edwards ERP system. This easy backend integration facilitated an easy and smooth future transition to enterprise-wide adoption of automated data collection across multiple processing facilities on several continents.