Digitizing Time Out of Environment (TOE) and Auto-Population of Certification Forms.

The Challenge

A large global pharmaceutical processor manually tracked and recorded data about products’ refrigeration excursion times during production. The processor needed to migrate to automated tracking to improve process visibility for its customers.

The RFID READY Time Out of Environment Plug-in Solution

RFID READY built a system that digitizes data by auto-populating batch records and cold storage logs during production runs and packaging. Raw TOE data is captured using barcode and RFID tags. Data is then automatically input into TOE algorithms and used to populate and print batch records and cold storage log forms for manual signoff. The system also generates alerts about excessive TOE excursions during production so that products can be returned to refrigeration for temperature stabilization. The automated system provides certified customer-specific documentation.

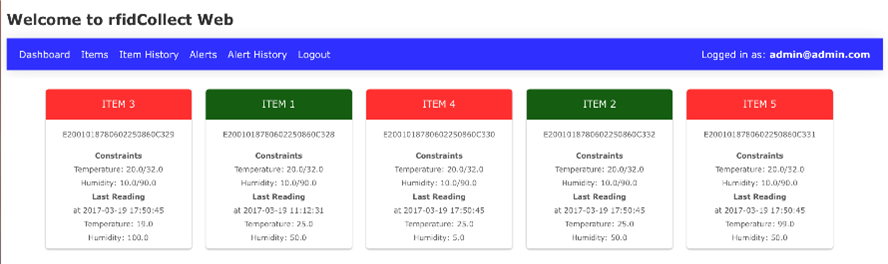

The RFID READY open-source management application provides a closed-loop system that digitizes what had been manual processes by automatically collecting TOE data and communicating it via a Web console for real-time visibility and customer documentation. The new system uses scans at strategic read points to track product movement, report alerts and notifications for events outside of set parameters, and print job logs as required by customers.

The Objective

To collect product TOE data and build a form digitization process that becomes a company standard for improved production efficiencies. The system needs to eliminate inadvertent product waste, improve labor utilization, and digitize product process run certification for customers.

The Solution

RFID READY’s TOE Web application, antennas and readers

The Results

The program provided visibility into single event and cumulative TOE for products, and satisfied the following requirements:

- eliminating errors in TOE tracking and time calculations

- setting alerts for approaching TOE time limits

- auto-generating batch record and cold storage log forms for manual signatures

- providing real-time dashboard visibility and electronic (PDF) record certification of job completion and work in progress for customers

- reducing manually generated documentation by creating digital standards within existing processing

- validating the ROI in labor savings from improved record accuracy and elimination of product waste and spoilage caused by inadvertent product excursions

Conclusion

The RFID READY TOE system eliminated manual tracking and saved many hours of error-prone, labor-intensive documentation. It provided the pharmaceutical company client with a real-time Web display of all TOE information. It included a RESTful Web service interface, designed with hooks to integrate into the company’s backend JD Edwards ERP system. This backend integration facilitated an easy and smooth future transition to enterprise-wide adoption of automated data collection across multiple processing facilities on several continents.